Facing Cement Failures?

Find the Solution.

Cement manufacturers worldwide struggle with key production challenges that impact efficiency, product consistency, and structural integrity:

- FLUCTUATING CLINKER COMPOSITION – Small variations in alite (C₃S), belite (C₂S), and aluminate (C₃A) affect cement quality, setting time, and long-term durability.

- INCONSISTENT QUALITY CONTROL – Traditional methods delay production and provide unreliable cement analysis, increasing waste and process inefficiencies.

- CHALLENGES WITH ALTERNATIVE MATERIALS – The integration of supplementary cementitious materials (SCMs) and alternative fuels complicates cement processing and phase stability.

- STRUCTURAL SAFETY RISKS – Poor cement phase identification leads to unpredictable curing times, impacting large-scale construction projects.

- HIGH OPERATIONAL COSTS – Inefficient cement production processes, manual testing, and rejected batches drive up expenses.

If these challenges impact your operations, it’s time to adopt a smarter approach.

Discover how advanced XRD cement analysis ensures real-time phase identification, process automation, and unmatched precision in cement manufacturing.

Know more from linevsystems.com

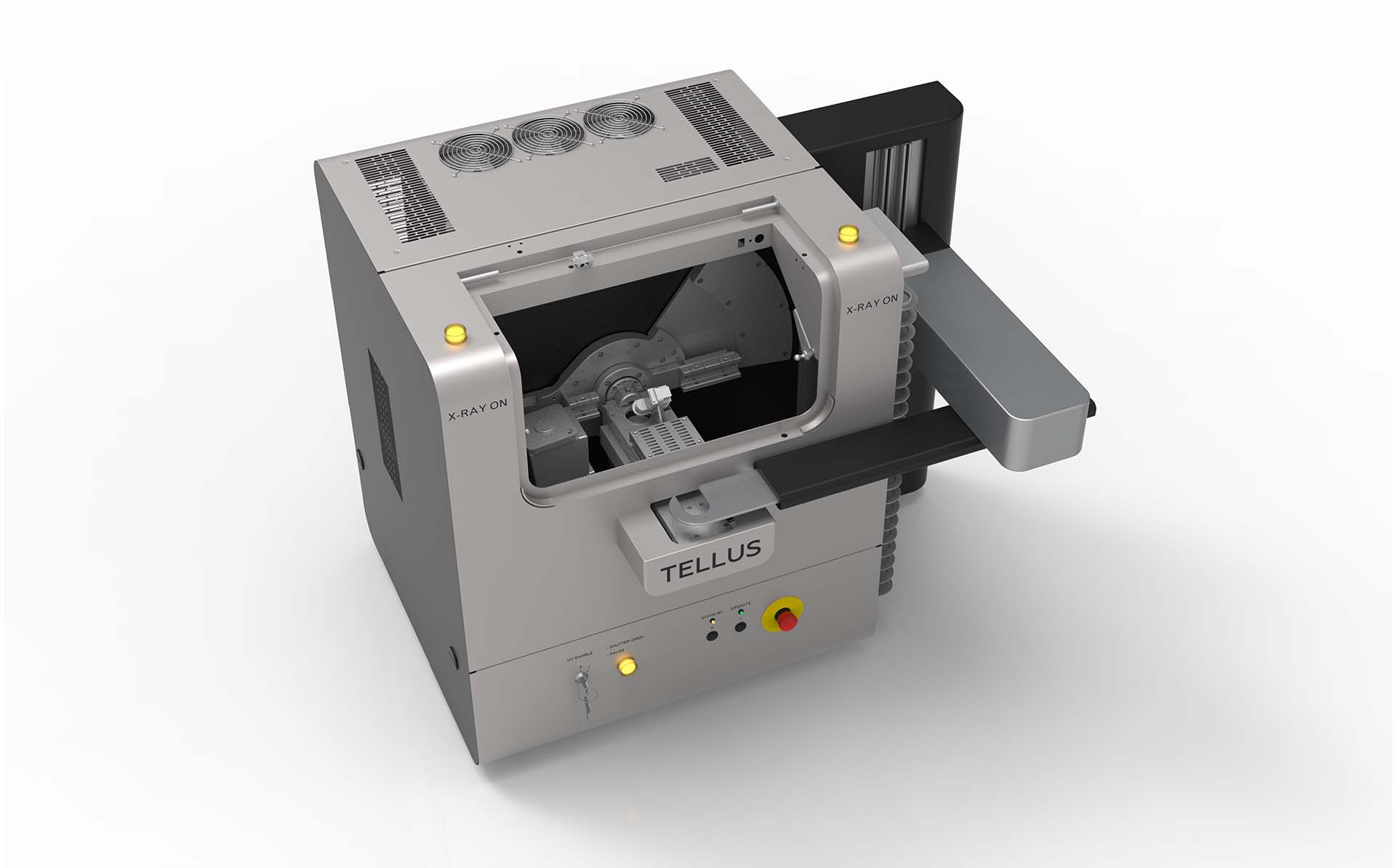

TELLUS Industry: Advanced XRD for Cement Quality & Process Control

Why XRD is Essential for Cement Manufacturing

Consistent cement quality depends on precise control over mineral phases in raw materials, clinker, and final cement blends. Traditional chemical methods like XRF determine elemental composition but fail to differentiate crystalline structures. X-ray diffraction (XRD) provides direct phase identification and quantification, ensuring accurate quality control and optimized cement production.

TELLUS Industry transforms cement analysis with a high-accuracy, automated XRD system tailored for cement manufacturers. With real-time phase quantification, it enhances kiln performance, product consistency, and cement strength.

Unlike chemical methods such as XRF, XRD reveals the true phase composition of cement, including polymorphs and amorphous content, which directly impact strength, setting time, and durability. According to ASTM C1365-18, XRD is a recognized reference method for quantifying crystalline phases in portland cement and clinker.

Precision at Every Stage of Cement Production

TELLUS Industry integrates XRD cement analysis at key production stages to ensure structural integrity and process efficiency:

- Raw Material Analysis: Determines cement raw material composition to optimize blending, reduce variability, and improve quality control.

- Clinker Quality Control: Quantifies alite, belite, aluminate, and ferrite phases, optimizing kiln operations and reactivity.

- Final Cement Characterization: Analyzes hydration phases such as gypsum, anhydrite, and ettringite to fine-tune setting time and compressive strength.

- Process Optimization: Supports real-time kiln adjustments, grinding efficiency, and cement production consistency using automated phase monitoring.

By leveraging advanced XRD analysis, TELLUS Industry delivers unmatched precision, consistency, and process efficiency in cement manufacturing. From raw material evaluation to final cement validation, its high-resolution detection, automated workflows, and real-time phase monitoring empower cement manufacturers to reduce production variability, optimize formulations, and ensure regulatory compliance. Designed for seamless integration into cement plants, it provides data-driven control for superior cement quality and long-term infrastructure durability.

TELLUS Industry: Unmatched Performance & Accuracy

Designed for high-throughput cement production, TELLUS Industry combines advanced XRD technology with precision, automation, and seamless process integration.

Its high-resolution detection system provides precise phase identification with an angular accuracy of ±0.02° (2Ө), ensuring consistent mineral composition monitoring at every stage of cement manufacturing.

Unlike traditional methods, TELLUS Industry features a fully automated goniometer, eliminating manual adjustments and delivering reliable, repeatable measurements. Phase quantification is completed in minutes, allowing for real-time process optimization.

With a compact benchtop design, it integrates seamlessly into cement labs and production facilities, offering advanced analytical capabilities without occupying excessive space.

The intuitive software suite includes automated phase identification, quantification, and reporting, reducing operator workload and minimizing human error in cement quality control.

TELLUS Industry empowers cement manufacturers with precise analysis, reduced material waste, and optimized efficiency—providing a cost-effective, fully automated solution for cement phase monitoring.

What You Can Analyze with XRD

- Clinker phases: Alite (C₃S), Belite (C₂S), Aluminate (C₃A), Ferrite (C₄AF)

- Hydration products: Ettringite, gypsum, anhydrite

- Free lime (CaOfree): Kiln control and reactivity

- Sulphate forms and ratios (SO₃)

- Amorphous SCMs (slag, fly ash)

- Phase ratios and polymorphic transitions

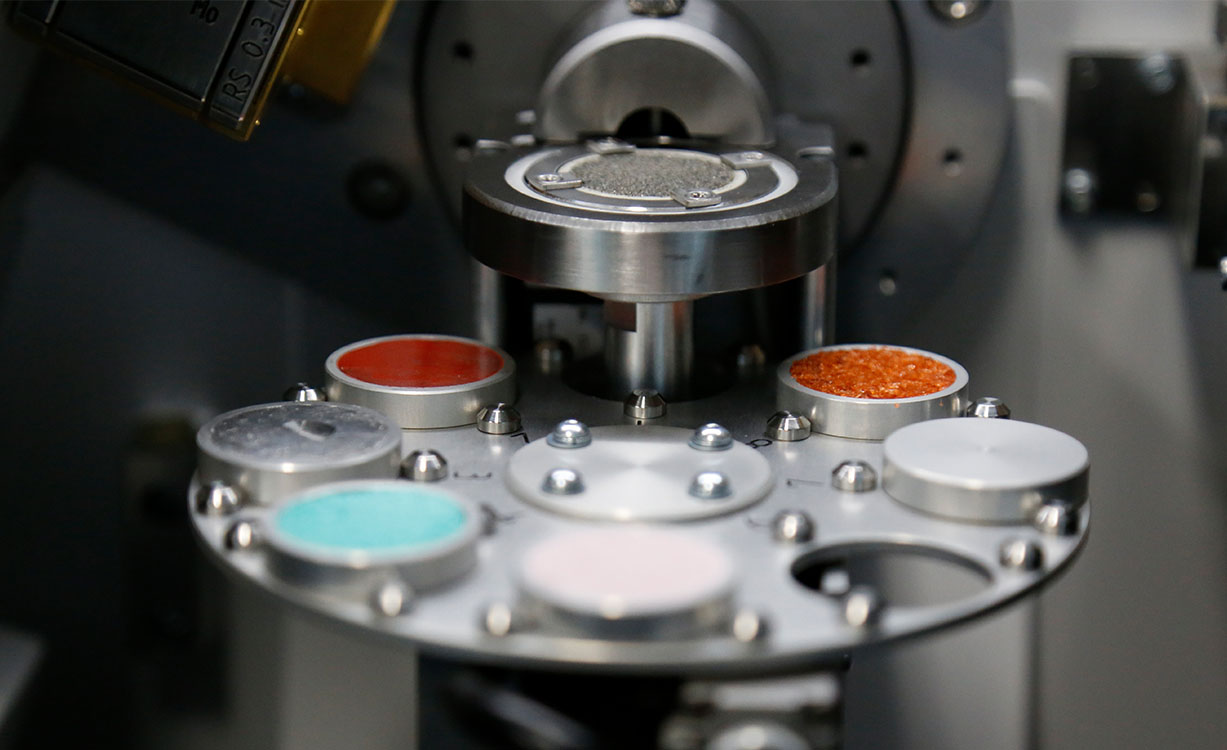

TELLUS Industry offers a range of accessories designed to enhance precision, efficiency, and adaptability in cement phase analysis. These add-ons improve sample handling, data accuracy, and seamless integration into cement production workflows:

- Automatic Sample Changer – Supports high-throughput XRD analysis, processing multiple samples sequentially with no manual intervention.

- Advanced Sample Holders – Secure and stabilize various cement sample types for optimal positioning during XRD scanning.

- Precision Calibration Standards – Certified reference materials ensure long-term measurement accuracy and data reliability.

- Environmental Enclosures – Minimize external interferences such as vibration, temperature fluctuations, and dust contamination.

- Integrated Vacuum Pump – Reduces background noise, improving the detection of low-concentration phases in cement analysis.

- Custom Software Modules – Additional automation, advanced data processing, and real-time cement quality control tools.

Key features

Automated High-Throughput XRD

Processes multiple cement samples with automated loading and rapid scanning, minimizing manual effort and delivering consistent, high-speed phase identification for cement quality control and process optimization.

Precision XRD Technology

The Theta/Theta vertical uncoupled goniometer with a 0.0003° (2θ) minimal step size enables high-resolution phase analysis, ensuring cement consistency, precise mineral identification, and compliance with industry standards.

Optimized for Cement Applications

Designed for clinker, cement, and supplementary materials, delivering precise mineral phase identification to optimize strength, setting time, and long-term durability in cement production and quality control.

Seamless Process Integration

The compact benchtop design with industrial-grade automation integrates effortlessly into cement labs and production workflows, enabling real-time quality monitoring and continuous process optimization.

Advanced Data & Reporting Software

TELLUS Industry uses Rietveld refinement and G-factor calibration to deliver fully quantitative results, even for amorphous and mixed-phase materials. Cement manufacturers can identify critical parameters such as CaOfree, C₃S/C₂S ratios, sulphate forms, and SCM content — all in real time, with traceable accuracy.

Built for 24/7 Industrial Use

Designed for continuous operation, its rugged, dust-resistant construction and internal water cooling system ensure long-term reliability in cement plants and high-throughput production environments.

Automated High-Throughput XRD

Processes multiple cement samples with automated loading and rapid scanning, minimizing manual effort and delivering consistent, high-speed phase identification for cement quality control and process optimization.

Precision XRD Technology

The Theta/Theta vertical uncoupled goniometer with a 0.0003° (2θ) minimal step size enables high-resolution phase analysis, ensuring cement consistency, precise mineral identification, and compliance with industry standards.

Optimized for Cement Applications

Designed for clinker, cement, and supplementary materials, delivering precise mineral phase identification to optimize strength, setting time, and long-term durability in cement production and quality control.

Seamless Process Integration

The compact benchtop design with industrial-grade automation integrates effortlessly into cement labs and production workflows, enabling real-time quality monitoring and continuous process optimization.

Advanced Data & Reporting Software

TELLUS Industry uses Rietveld refinement and G-factor calibration to deliver fully quantitative results, even for amorphous and mixed-phase materials. Cement manufacturers can identify critical parameters such as CaOfree, C₃S/C₂S ratios, sulphate forms, and SCM content — all in real time, with traceable accuracy.

Built for 24/7 Industrial Use

Designed for continuous operation, its rugged, dust-resistant construction and internal water cooling system ensure long-term reliability in cement plants and high-throughput production environments.

From automated sample loading to final report generation, the system minimizes operator intervention, reducing human error, enhancing accuracy, and accelerating cement quality control for more efficient decision-making.

A compact, dust-resistant benchtop system with internal water cooling, designed for 24/7 continuous operation in cement plants, ensuring long-term stability, durability, and reliability in demanding industrial environments.

High-resolution 1D and 2D photon-counting detectors enable precise phase quantification, ensuring batch-to-batch consistency, compliance with ASTM, EN, and ISO standards, and minimizing variability in cement production.

Product Videos

Technical data

X-ray System

| X-ray generator | 40 kV, 15 mA (600 W) or 30 kV, 10 mA (300 W) |

| X-ray tube | 1.5 kW, Cu, ceramic focus 0.4×8 mm |

| X-ray emission | Less than 0.3 μSv/h (complying with <1 μSv/h at 10 cm) |

| X-ray shielding | Multi-level operator protection |

Goniometer

| Type | Theta/Theta vertical, independent arms |

| Radius | 150 mm |

| Scanning range | -6° to +154° (2θ) |

| Minimal step | 0.0003° (2θ) |

| Positioning accuracy | ±0.01° (2θ) |

| Scanning speed | 0.01° to 600°/min |

Sample Handling

| Automatic sample changer | Built-in, supports 40 mm & 51.5 mm sample holders |

| Sample positioning | Automated precision alignment |

| Throughput | Continuous, high-throughput workflow |

Software & Data Processing

| Operator software | TellusCon – automated control, diagnostics, reporting |

| Data analysis software | ALMAZ – automated phase identification & Rietveld refinement |

| Database support | COD & ICDD PDF-2 (optional) |

Environmental & Power Requirements

| Operating temperature | +10°C to +35°C (optimal +18°C to +28°C) |

| Power supply | 110-264 VAC, single-phase |

| Power consumption | 700 W (300 W generator) / 1000 W (600 W generator) |

| Cooling system | Internal closed-circuit water cooling |

X-ray System

| X-ray generator | 40 kV, 15 mA (600 W) or 30 kV, 10 mA (300 W) |

| X-ray tube | 1.5 kW, Cu, ceramic focus 0.016×0.31 in |

| X-ray emission | Less than 0.3 μSv/h (complying with <1 μSv/h at 4 in) |

| X-ray shielding | Multi-level operator protection |

Goniometer

| Type | Theta/Theta vertical, independent arms |

| Radius | 5.91 in |

| Scanning range | -6° to +154° (2θ) |

| Minimal step | 0.0003° (2θ) |

| Positioning accuracy | ±0.01° (2θ) |

| Scanning speed | 0.01° to 600°/min |

Sample Handling

| Automatic sample changer | Built-in, supports 1.57 in & 2.03 in sample holders |

| Sample positioning | Automated precision alignment |

| Throughput | Continuous, high-throughput workflow |

Software & Data Processing

| Operator software | TellusCon – automated control, diagnostics, reporting |

| Data analysis software | ALMAZ – automated phase identification & Rietveld refinement |

| Database support | COD & ICDD PDF-2 (optional) |

Environmental & Power Requirements

| Operating temperature | 50°F to 95°F (optimal 64°F to 82°F) |

| Power supply | 110-264 VAC, single-phase |

| Power consumption | 700 W (300 W generator) / 1000 W (600 W generator) |

| Cooling system | Internal closed-circuit water cooling |

Learn more

TELLUS Industry goes beyond hardware—its intelligent software transforms raw XRD data into actionable insights for cement manufacturers. Every mineral phase, every variation, and every critical compound is automatically detected, analyzed, and quantified, eliminating manual errors and streamlining cement quality control.

TellusCon Operator Software ensures seamless system control, real-time monitoring, and automated calibration, minimizing downtime and maintaining consistent accuracy across cement production batches. With an intuitive interface, operators can set scanning parameters, track results, and integrate data into LIMS and process control systems.

The ALMAZ Data Analysis Suite enables high-precision phase quantification, identifying alite, belite, aluminate, ferrite, and hydration phases within minutes. Its advanced algorithms remove background noise, correct distortions, and apply Rietveld refinement for precise cement phase analysis.

For cement producers, this means faster decision-making, reduced production variability, and total confidence in material quality. No more guesswork—just clear, reliable data for optimizing cement composition, improving consistency, and ensuring compliance with ASTM and EN standards.

FAQ

What is XRD analysis in cement production?

X-ray diffraction (XRD) is a technique used to identify and quantify the mineral phases in cement, clinker, and raw materials. It provides critical insights into cement composition, including alite, belite, ferrite, aluminate, and amorphous content—factors that directly affect strength, setting time, and durability.

Why is XRD better than XRF for cement quality control?

XRF provides elemental composition, but only XRD reveals the crystal structure and phase composition. XRD can detect polymorphic forms, hydration products, and free lime (CaOfree), making it essential for precise clinker analysis and optimizing cement performance.

How fast can XRD analyze cement samples?

Modern XRD systems like TELLUS Industry deliver full phase analysis of clinker in under 7 minutes and free lime results in 60 seconds. Automated sample handling and software-driven processing ensure fast, accurate results for high-throughput cement production.

What phases can XRD detect in cement and clinker?

XRD detects key cement phases such as alite (C₃S), belite (C₂S), aluminate (C₃A), ferrite (C₄AF), gypsum, ettringite, anhydrite, and SCMs like slag or fly ash. It also quantifies amorphous content and monitors hydration progress.

Is XRD compliant with cement industry standards?

Yes. XRD is officially recognized by ASTM C1365-18 as a reference method for quantitative phase analysis in cement and clinker. It supports compliance with ASTM, EN, and ISO quality standards across the cement industry.

The fastest way to hear back from us is to fill the contact form below. One of our expert team will get back to you as soon as possible.